Scottsdale, Arizona – High Speed Interconnects LLC (HSI) alongside with OmniVision Technologies Inc. continue to execute their collaboration to solve a myriad of image-capture and transmission challenges across a broad range of endoscope's, catheter, and guide-wire based applications. Expanding their relationship, HSI and Omnivision are delivering turnkey imaging solutions based on HSI's cable technology and OmniVision's OV6946, OV6948 image sensors, wafer-level lens, and back-end image signal processor.

Industry analysts are reporting the demand for minimally invasive medical procedures enabled by endoscope, catheter, or guidewire-based devices is growing rapidly, driven by multiple socioeconomic factors such as increasing healthcare expenses, hospital-acquired infections (HAI), an aging population, and the rise of the middle class in the developing world. Consequently, hospitals are actively investing in endoscopic, catheter, and guidewire technologies. Additionally, growing concerns about cross-contamination and HAIs caused by reusable endoscopes are driving the need for cost-effective, single-use, endoscopes, catheter, and guide-wire based solutions.

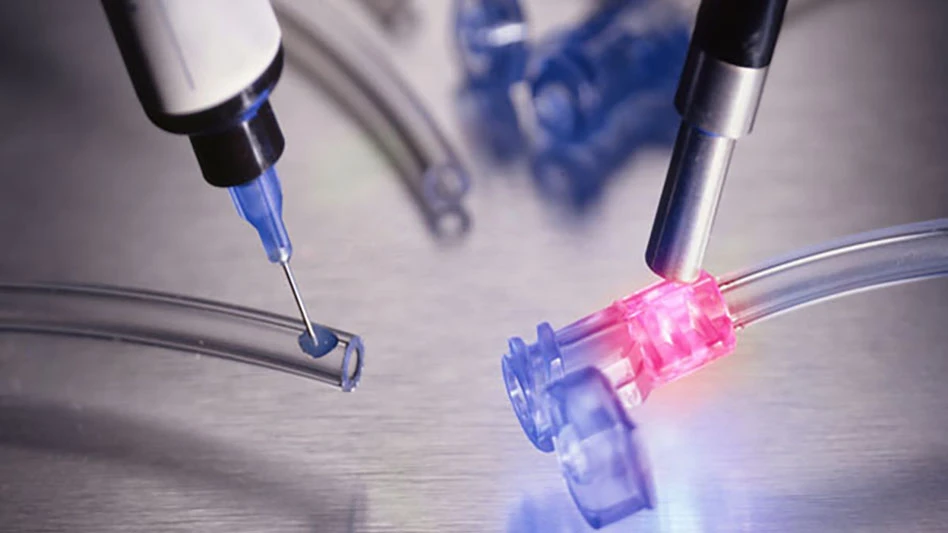

Ensuring an endoscope, catheter, or guidewire delivers top quality images requires capturing the images with a best-in-class sensor, then transmitting the signal (and power) via a micro-miniature cable from the distal-tip to proximal-end. HSI's highly-engineered cable must be capable of transmitting images across analog and MIPI interfaces, then be precisely terminated to fine-pitch Omnivision image sensor pad's. Despite of length, the imaging solution must withstand insertion loss, noise, and cross-talk, plus be small enough to fit inside the inner diameter of an endoscope, catheter, or guidewire while sufficiently cost-effective for any single-use medical device application.

Sign up for the weekly newsletter…know the latest in the medical design and manufacture market.

"The engineering expertise of top-tier innovators is essential in meeting the key requirements for high performance, small diameter disposable endoscopes," says Tehzeeb Gunja, senior product marketing and business development manager at OmniVision. "HSI has considerable expertise with its unique extrusion, applied materials, and termination technology platforms to deliver such a wiring subsystem, which couples perfectly with OmniVision's OV6946 and OV6948 image sensors. Together, we believe we can offer high volume, cost-effective solutions that can meet medical device manufacturers' stringent imaging and cabling expectations."

"Leveraging our highly-engineered coaxial cable extrusion and manufacturing capabilities in Portland, Oregon, and a low-cost country assembly operation in Hermosillo, Mexico, enables us to address customer expectations from product development to mass production," says Antonio De La Rosa, founder, CEO, and manager of HSI. "We are delighted to be strategically engaged with OmniVision to deliver cost-effective, high-performance image-capture assembly solutions that allow medical device manufacturers to develop single-use devices for a growing medical market."

Latest from Today's Medical Developments

- US metalworking machinery orders through November 2025 reveal 17.8% increase from first 11 months of 2024

- Precision metering pumps for medical device manufacturing

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- Velosity opens precision development center to accelerate medical device product launch

- A look at the latest in the defense industry

- EMCO manufacturing showroom offers customers hands-on milling, machining engagement

- Workholding Roundtable to feature expert insights on a booming market

- Ilika, Cirtec advance strategic partnership to commercial level