Bird-In-Hand, Pennsylvania – Product designers and engineers have a new resource to help prevent premature failure and costly damage caused by a form of wear to threaded parts called galling. Vallorbs Jewel Company’s “Eliminating Galling” Tip Sheet provides design engineers with information about galling, its negative effects, and effective preventive strategies.

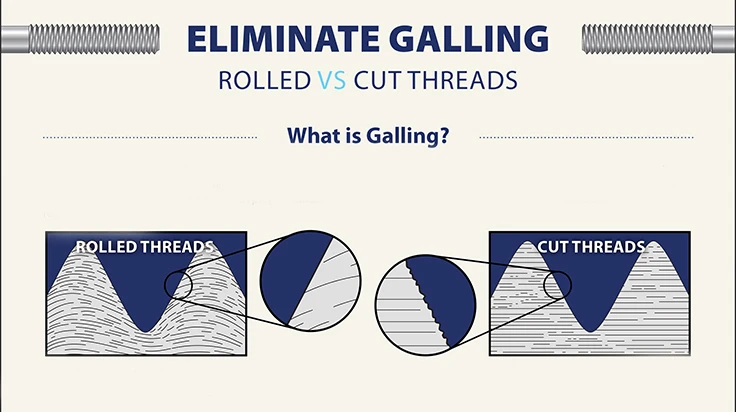

Galling is caused by friction between sliding metal surfaces and can lead to contamination, seizing, and loosening of threaded parts. Proper lubrication is one preventive strategy, but specifying rolled vs. cut threads is another effective way to eliminate galling. Rolled threads are smooth and free of tears and chatter, which are common starting points for galling.

“We have identified some solutions that can prevent galling and its negative effects on threaded parts,” said Ken Rinier, general manager at Vallorbs. “Most design engineers are unaware that thread rolling is an effective solution, so our goal is to help these engineers understand the causes of galling and when to choose rolled threads for galling prevention.”

Product designers and engineers designing components for high-precision industries, such as medical, aerospace, nuclear, and food processing are encouraged to download the “Eliminating Galling” tip sheet. Choosing the right preventive strategy for galling can significantly improve product quality and costs.

Source: Vallorbs

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025