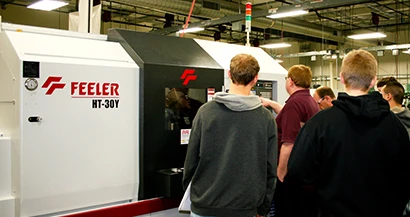

Officials from Methods Machine Tools recently donated the use of a FEELER VMP-580 CNC vertical machining center and a FEELER HT30-Y Turning Center to Ivy Tech Community College’s Orthopedic and Advanced Manufacturing Training Center (OAMTC) in Warsaw, Ind.

Methods is providing the new machines to Ivy Tech for instructional use in its curriculum during the 2012-13 academic year, including in its Advanced Manufacturing program and the Orthopedic Quality Standards and Technical Skills certificate program. Methods officials intend to replace the machines with the latest models in subsequent academic years.

According to Ivy Tech North Central Chancellor Thomas Coley, “This generous donation from Methods ensures that Ivy Tech students will always be training on the most up-to-date, state-of-the-art equipment available. Coursework and training at the OAMTC already meets rigorous standards and students will now have the added value of experience on always-current machines. Employers who hire our graduates will also see the benefit of new employees who have a wider range of machine-related experience.”

"One of the key issues facing our industry is the shortage of skilled, qualified machinists," explains Dale Hedberg, FEELER product manager at Methods. "Over the years, we have partnered with different technical schools, colleges, and universities across the country to help train the workforce. The students get a great education on high-tech equipment, the industry gets trained people, and students leaving here know our equipment."

The FEELER machines feature extensive engineering by Methods, the exclusive FEELER importer in North America. Designed to provide users unsurpassed performance and value, FEELER machines are very well equipped for the demands of the medical, aerospace, energy and other industries.

The FEELER HT30-Y turning center features linear guideways on the X and Z-Axis, 30° slant bed construction and a FANUC 18i-TD Control. The HT30-Y machine offers a 3,500rpm, 30hp spindle with a hydraulic chuck diameter of 10" (254mm) and a bar capacity of 3" (78mm). X-axis travel is 7" + 3.2" (178mm + 82mm), Y-Axis travel is 3.9” and ±2” (100mm ±50mm), and Z-axis travel is 31.3" (795mm) on the HT30-Y. It also includes a 12-station turret and offers a maximum turning diameter of 14" (356mm) and a maximum turning length of 27.75" (705mm).

The FEELER VMP-580 machine features a 10,000rpm spindle with 15hp, linear guideways on X- and Y-axis and boxways on the Z-axis. X-axis travels range from 580mm to 1,100mm (23" to 43"), Y-axis travels range from 420mm to 610mm (16.5" to 24") and Z-axis travels are from 510mm to 600mm (20" to 23.6"). The VMP-580 also provides a 24-tool automatic tool changer and a standard FANUC 0i-MD control.

Latest from Today's Medical Developments

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor