The final edition of this three-part medical machining series from Sandvik Coromant looks at the metals used in medical devices, their properties, and why each is selected for certain medical applications.

Most metals used to create life- saving objects fall into a group known as heat resistant super alloys (HRSA). These tough materials are widely used in the medical industry due to their high strength, hardness, and corrosion resistance, as well as their ability to retain these properties even at elevated temperatures.

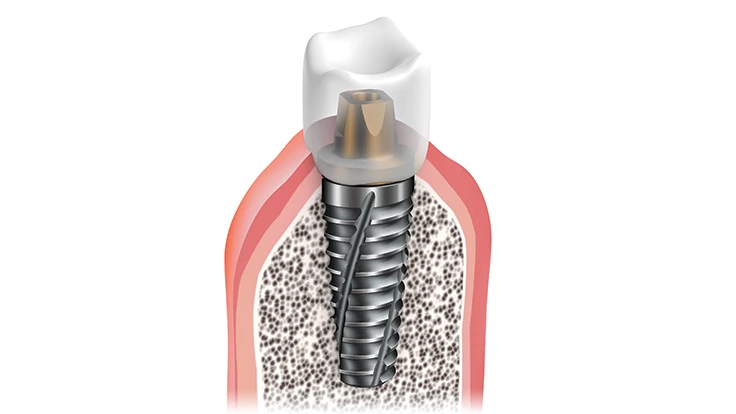

These biocompatible metals must not provoke immune responses from the human body or leach harmful minerals into the patient across time. For permanent implants, metals should also show a tendency toward osseointegration, meaning that they will gradually meld with the surrounding bone tissue and connective tissue and not come loose requiring surgical replacement after a few years.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025