3D-Micromac AG, Chemnitz, Germany, and EOS GmbH, Krailling, Germany, are bringing their respective technological knowledge in the area of Micro Laser Sintering technology (MLS) into a new corporation. The goal of establishing 3D MicroPrint GmbH is to advance the development and commercialization of the new MLS technology, and to identify and establish more solutions in the field of micro technology.

3D-Micromac AG and EOS GmbH have been developing Micro Laser Sintering technology together since 2006. The first system successfully began operation at a German research institute earlier in 2013.

Dr. Hans J. Langer, founder and CEO of EOS GmbH remarks: “Demand for very small parts which are difficult to manufacture using conventional processes is rising tremendously. Micro Laser Sintering provides solutions for three major trends: individualization, functional integration, and miniaturization.”

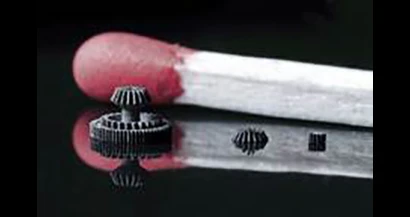

Joachim Göbner, one of the business managers of 3D MicroPrint, adds: “Working with layer thicknesses of ≤5µm, focus diameters of ≤30µm and powder particle size of ≤5µm, the MLS technology opens up new dimensions. With MLS it is even possible to produce moveable component assemblies.”

Tino Petsch, CEO of 3D-Micromac AG continues: “Our timing is virtually perfect. The current 3D printing hype shows that our investment in the development of Micro Laser Sintering systems was exactly right. Together we now offer a trend-setting solution that opens up new approaches in product development and manufacturing for our customers.”

Göbner, formerly project head MLS at EOS and head of the technical center Chemnitz, and Petsch, CEO of 3D-Micromac, were appointed as business managers of 3D MicroPrint. The company’s headquarters is located in Chemnitz.

3D MicroPrint has already moved into new premises on the Chemnitz Smart Systems Campus. The new location brings a major expansion of production space. Development and service capacities are also being expanded.

Background information on Micro Laser Sintering technology

Micro Laser Sintering is an Additive Manufacturing technology. Based on digital, 3D-design data, parts are built from metal powders, layer by layer, using a laser beam. The process is also known as industrial 3D printing.

MLS enables the production of parts with complex 3D structures, where conventional manufacturing processes reach their limits. Even a lot size of one part can be produced at reasonable cost-per-part. The technology offers a high degree of freedom of design, and the capacity to integrate and optimize functionality. Individualization of products even in series production processes can be accomplished without difficulty. Target applications include nozzles for the automotive industry, components for medical devices, or the individualization of jewelry. Aside from that, a growing demand for micro-parts can be observed in the areas of mold making and aerospace technology.

Source: EOS GmbH Electro Optical Systems

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025