CREDIT: VELOSITY

During this year’s MD&M West, Velosity – provider of state-of-the-art custom contract manufacturing, injection molding, precision machining, and tool building for highly regulated devices – announces the launch of the Velosity Engineering, Launch and Optimization Lab at its facility in Brooklyn Park, Minnesota. The Velosity Lab is a precision machining development center that accelerates new product launches, improves part performance, and strengthens strategic partnerships with OEM customers in the medtech and defense markets.

“This investment demonstrates Velosity’s commitment to helping our customers succeed,” says Dave Hemink, Velosity chief executive officer. “By creating a dedicated development environment, we’re not just improving speed and efficiency – we’re raising the standard for customer trust, collaboration, and innovation.”

Along with the announcement of the new lab, Velosity experts will also present during two educational sessions at MD&M West, sharing more about Velosity’s focus on supplier collaboration and its expanding Environmental, Social and Governance (ESG) program.

Velosity Engineering, Launch and Optimization Lab

The new Velosity Lab will expand the opportunity for bringing new medical devices to life. Previously, development work was performed on production machines, creating delays, scheduling conflicts and limited flexibility. The Velosity Lab addresses these challenges by providing a dedicated environment for early-stage development, guided by a Phase Gate Development Process that ensures parts move efficiently from concept to production once designs are validated.

Key benefits of the Velosity Lab include:

- Faster time-to-market: Dedicated development equipment reduces lead times for functional samples from 4 to 6 months to just 2 to 3 weeks, enabling rapid iteration and delivery.

- Continuous improvement: The lab supports enhancements to existing production parts without impacting ongoing manufacturing flow.

- Customer trust and innovation showcase: Tangible prototypes and agile development foster stronger OEM partnerships, build internal champions, and highlight Velosity’s commitment to quality, speed and operational excellence.

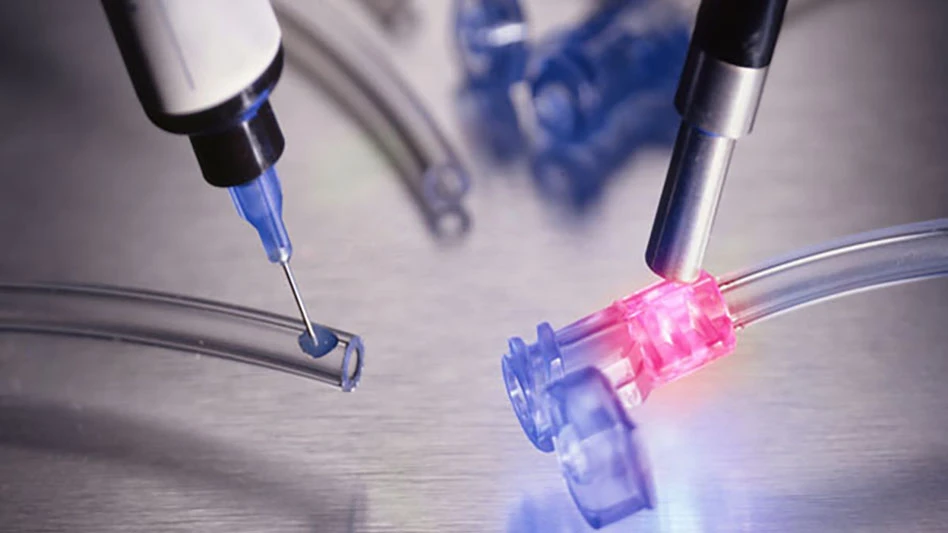

Equipped with advanced machining and inspection technology, the Velosity Lab features Citizen Swiss machines, 3-, 4-, and 5-axis vertical milling machines, and wire EDM. A dedicated quality lab with state-of-the-art metrology tools, including the OGP Quest 300 and Hexagon Global CMM, ensures precision, efficiency, and reliability at every stage of development.

The Velosity Engineering, Launch and Optimization Lab represents a multi-million-dollar investment in equipment and infrastructure, positioning Velosity as a top-tier supplier for OEM medical and defense customers and reinforcing the company’s long-term growth strategy.

ESG and supplier collaboration education sessions at MD&M West

Along with showcasing its investment in the Velosity Lab, Velosity will also be sharing expertise during two educational sessions Wednesday, Feb. 4 at MD&M West. The first, titled “Driving Medical Device Excellence: Supplier Collaboration for Accelerated Market Access”, features Hemink and Michael Schaller, medical device executive at Edwards Lifesciences, offering insights on the importance of strategic partnerships between device manufacturers and contract manufacturers, and ways to strengthen the collaboration between the two in order to quickly and successfully get products to market.

The second educational session, titled “How to Develop an ESG Program that Drives Operational Efficiency and Economic Impact”, will discuss why having a defined ESG program is critical for customer expectations and satisfaction along with the company’s sustainability into the future. Panelists will share how Velosity shaped its ESG policy, put it into action and in turn improved efficiency across the company. The panel will include Hemink; Greg Zemple, Velosity environmental, health and safety manager; and Kate Tetreault, Velosity ESG consultant and ESG associate at Graham Partners. Janet Janiszewski, Velosity chief human resources officer (CHRO), will moderate the panel.

Visit Booth #3011 at MD&M West, Feb. 3 to 5 to learn more about the initiatives and ways Velosity is advancing innovation in medical device manufacturing.

Latest from Today's Medical Developments

- A look at the latest in the defense industry

- EMCO manufacturing showroom offers customers hands-on milling, machining engagement

- Workholding Roundtable to feature expert insights on a booming market

- Ilika, Cirtec advance strategic partnership to commercial level

- Engineered fluids offer full lifecycle solutions for medical device development

- Syringe-less injector system for diagnostic imaging obtains fourth FDA clearance

- Hohenstein Medical debuts enhanced medical device testing capabilities

- Arterex unveils unified brand identity