CREDIT: AMERICHEM

As medical device manufacturers face mounting pressures to reduce environmental risk, improve traceability, and accelerate product development, Americhem is preparing to highlight a suite of new technologies that reflect these industry shifts at Pharmapack (Paris) and MD&M West (Anaheim) in early 2026.

The company, known for its healthcare-focused polymer compounds and masterbatches, will showcase five key technologies, each designed to respond to the technical and regulatory complexities facing modern medtech – particularly in areas such as connected care, self-administered delivery, and robotic-assisted interventions. Among the engineered solutions:

- PFAS-free internally lubricated compounds: Under the EcoLube MD umbrella, Americhem is advancing a portfolio of tribological materials engineered to reduce friction and wear without relying on PFAS additives. Applications include auto-injectors, wearable pumps, and precision robotic tools.

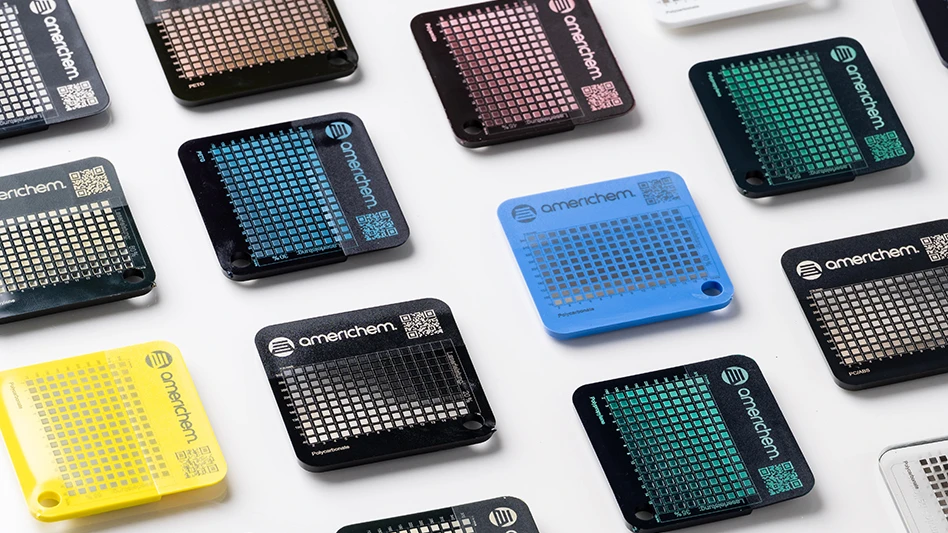

- Laser marking-ready thermoplastics: Materials that enable high-contrast, permanent part identification directly on plastic components – eliminating the need for labels or inks in cleanroom environments.

- High-performance transparent alloys: New polymer blends offering an alternative to incumbent clear materials, with improved sterilization durability and toughness for structural medical components.

- Regulatory-ready color masterbatch: Additions to the ColorRx line aim to help OEMs navigate color compliance challenges, offering ISO 10993-tested, locked formulations that align with clean compounding and cGMP manufacturing standards.

- nDryve additive for medical nonwovens: A PFAS-free, in-melt surface modifier targeting nonwoven applications such as surgical gowns and hygiene drapes, developed in response to growing demand for fluorine-free fluid repellency.

Americhem is actively engaging with OEM partners to co-develop and validate them for next-generation device applications. The company reports continued double-digit growth in its healthcare segment, supported by its ISO 13485-certified facilities in the U.S. and Denmark and upcoming expansion into China in 2026.

Americhem will also participate in the SPE Minitec Conference held during MD&M West, joining technical discussions on materials innovation for evolving care models.

“There’s a clear shift happening – material choices are now deeply tied to sustainability goals, regulatory scrutiny, and device functionality,” says Matt Miklos, vice president of Corporate Strategy and M&A at Americhem. “What we’re bringing to these shows is not a catalog – it’s a pipeline of engineered solutions designed to be customized, scaled, and validated in partnership with OEMs who are navigating that complexity every day.”

Americhem’s approach emphasizes long-term material consistency, global compliance, and early design collaboration – factors increasingly prioritized by engineering and R&D teams charged with building the next wave of medical devices.