Experienced silicone products maker, General Silicones (GS), is introducing its Compo-SiL technology to the market. Compo-SiL solves the critical problem of the low surface energy of cured silicone by enhancing the surface energy with the help of an ultra-thin PU-based modified layer. This innovation allows the process and bonding of cured silicone efficiently during mass production with surfaces safely and in a lasting way.

Adhesion problems of cured silicone rubber

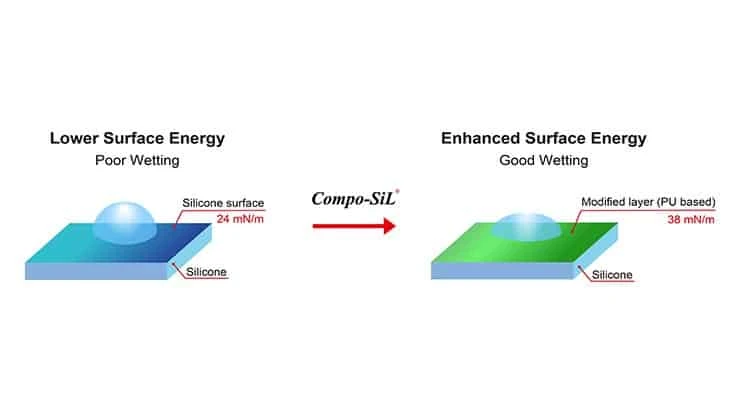

Silicone is one of the bio-friendly and sustainable materials of choice for many large volume applications in industries like health care, electronics, automotive, aerospace, industrial assembly, building, textile, etc. Despite that, the low surface energy (LSE) of 24mN/m of cured silicone rubber makes it difficult to use for good adhesion. Finding an ideal solution is still a challenge. There is an essential need for a bio-friendly silicone substrate with good surface adhesion properties for diverse application areas.

Increasing silicone’s low surface energy from 24mN/m to 38mN/m

Compo-SiL by General Silicones resolves silicone adhesion and bonding problems from the lower surface energy of silicone by chemically bonding silicone sheets with an ultra-thin polyurethane-based modified layer. The custom patented technology of General Silicones binds the modified layer to the silicone and therewith enhancing the surface energy level to 38mN/m.

Conventional activation of low surface energy of silicone

Current adhesive technologies and primers from bonding LSE silicone with other surfaces have difficulty controlling reaction kinetics and the chemical composition. Other surface pretreatment techniques, including corona, plasma, flame, etc. can enhance the surface energy of silicone surface, but have the disadvantages of durability, cost, complexity and may even present environmental or safety issues.

For all the cases of different modified PU laminate with Compo-SiL, tests by GS showed cohesive failure within the adhesive layer or cohesive failure in the adherend, demonstrating the strong bonding between silicone and modified layer of the Compo-SiL technology of General Silicones.

Customization of the silicone layer of Compo-SiL

GS offers a diverse series of silicone with unique properties for various applications. With high expertise in silicone formulation, several processing methods, and state of the art R&D. GS customizes silicone properties according to customer demand and ships globally. Color (transparent, translucent, or any), the hardness of silicone material (25 to 80 shore A), thickness (customized), tensile strength (30Kgf/cm2 to 100Kgf/cm2), tear strength (10Kgf/cm to 30Kgf/cm), and elongation (200% to 800 %) are all customized according to specification.

Silicone-based Compo-SiL series can:

- Bond to other surfaces where cured silicone substrates cannot

- Make the manufacturing process easier for printing and lamination purposes

- Reduce the use of solvent, primers, and other chemicals

- Offer long-term durability

- Provide various designs and customizations

- Lower manufacturing costs