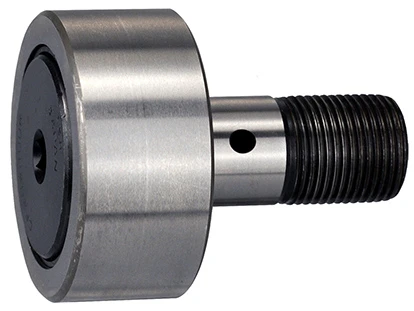

Parsippany, New Jersey — IKO’s standard, hex head cam followers are available in stud diameters from 3 to 30mm and include a re-lubrication root that can be accessed from three separate holes for ease of service, no matter the orientation. Easily installed using a hexagonal wrench, these cam followers are widely used in machine tools, industrial robots, electronic devices, and office automation equipment.

Check out the 2016 IMTS Conference!

These hex head cam followers are available in a caged type or a full complement type. The caged version features a small coefficient of friction and is suitable for high rotational speed, while the full complement style is suited for heavy loads at low rotational speed. IKO offers its cam followers in high carbon steel or stainless steel for applications where superior corrosion resistance is required. Other options include a choice of crowned or cylindrical outer diameters, and sealed or shielded sealing structures.

IKO’s C-Lube unit can be added to its hex head cam followers to reduce maintenance time and costs. The C-Lube Unit contains a solid lubricant that is automatically distributed onto the cam follower's outer ring and then onto the mating track surface to provide abrasion protection and increase corrosion resistance. This negates the need for periodic oiling.

Source: IKO International Inc.