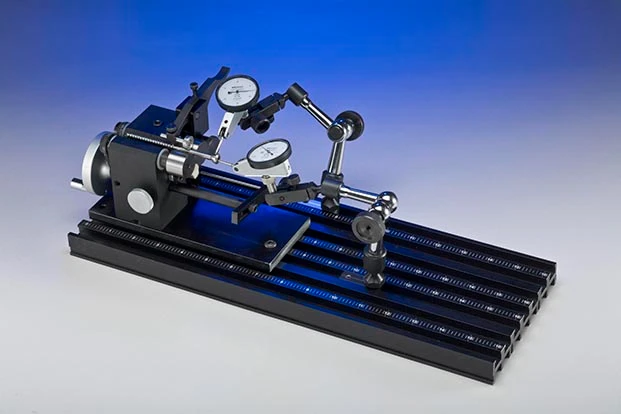

Bloomfield, Connecticut - Recognized as the industry leader in thread inspection systems for dimensional conformance verification, Johnson Gage will display will be the JCR Runout and Concentricity Inspection System for verification of cylindrical runout or concentricity for high-precision medical parts and other Swiss machining parts. The JCR incorporates precision datum rolls, a unique upper tension roll assembly, and integral axial stop pins to assure proper part staging and absolute gage accuracy. In addition, the company will feature its Thread Inspection System for the verification and in-process control of reverse-angle buttress threads commonly used in anti-splaying medical devices such as orthopedic implants. Available for either external or internal thread forms, the system is suitable for both inspection and manufacturing environments. Common applications include design validation, dimensional inspection and conformance, initial manufacturing and tool verification, and in-process determination of capability degradation.

Check out the 2016 IMTS Conference!

Source: Johnson Gage Corp.