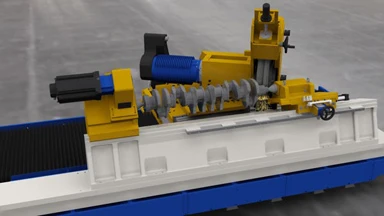

Cinetic Landis Corp. ECOFLEX line of CNC precision cylindrical grinders. Cinetic Landis addressed two key issues—flexibility and economy of ownership—in designing the ECOFLEX line of traverse/plunge/contour CNC grinders. The machine features a modular platform that enables Cinetic Landis to address a variety of customer needs.

The ECOFLEX grinder can accommodate either conventional aluminum oxide or superabrasive CBN grinding wheels. To further enhance flexibility, the ECOFLEX grinder incorporates a B-axis that allows the use of multiple spindles and programmable angles to accommodate combined operations in a single fixture.

The highly flexible design helps overcome the shortage of skilled machine operators and responds to the drive towards lean by enabling grinding processes that capture more operations in a single machine. Machining multiple features on a part in a single fixturing also contributes to better geometric accuracy.

Cinetic Landis has incorporated linear motors for its grinders’ wheel in-feed systems for many years. But the new ECOFLEX grinder also incorporates a linear motor drive with precision rails for the traverse axis that eliminates frictional “stick-slip” positioning constraints that were symptomatic with traditional hand-scraped, cast iron vee- and flat-way construction. As a result, Cinetic Landis engineers expect the new ECOFLEX grinder to attract business for parts such as large rolls, drive shafts and similar components. “Historically, with traverse ground parts you expect to have some type of crown in the middle, which was meticulously achieved by scraping in the way system,” explained Tim Hykes. “Now, we’ll be able to make the machine run perfectly straight in its nominal condition and then program contour crowns, compound crowns or crowns with tapers, or you name it.”

The high rotational accuracy and stiffness of the grinder’s hydrostatic wheel spindle enable faster feed rates, improved finishes and provide consistent, maintenance-free accuracy. This, combined with the machine’s other critical components and the powerful, open-architecture Landis 6400 CNC, enables the ECOFLEX to meet micron level total dimensional and geometric tolerances and sub-micron level surface finishes.

Environmentally Friendly Design

The other main objective in developing the new ECOFLEX grinder line was to economize energy losses wherever possible in the machine. Some of the major targeted areas include frictional losses and fluid power system losses in an effort to reduce the non-productive energy losses in the machine to an absolute minimum. Major components used to achieve energy optimization include linear motors on the X- and Z-axis ways; anti-friction, rail-type way systems for cross slides and wheel head feed; a low-power hydrostatic spindle that requires no chiller; and an advanced coolant management design that isolates the grinding coolant from the machine structure, optimizing the machine’s thermal stability.

“We took a holistic look at the energy consumption in the design of the new ECOFLEX grinder,” says Hykes. “There are several facets to that; the obvious one is how many kilowatt hours are consumed by the machine on a job. But the other things to consider are the energy that must be removed from the working fluids and the plant environment, as well as how much energy the machine consumes in the idle state. Owners don’t like to think of their machines in an idle state, but in practice, it is a reality. The ECOFLEX will have a fraction of the idle power consumption of traditional grinders.”

Cinetic Landis engineers say the new ECOFLEX grinders offer significant potential savings for the machine owner, including less energy used up front as well as less energy that must be removed from the working fluids and the plant environment.

Finding a Niche

When Cinetic Landis undertook market research for the ECOFLEX product line, company executives recognized that they needed to find a market niche where they could use their particular skills and capabilities, and avoid the commodity end of the market. To that end, they determined that a 1.5m part length was the break point where applications tend to move from the commodity grinder realm to the more specialized, applied machine realm. The base machine is targeted for parts up to 1.5m in length and diameter of up to 400mm. A 750mm part swing is optionally available.

“We have a very flexible, configurable machine platform that can be expanded in length and swing capacity and can easily be adaptable to a variety of components,” says Tim Hykes. “We’re gratified to have accomplished our flexibility and environmental design goals while achieving the level of precision that customers have traditionally expected from Cinetic Landis equipment.”