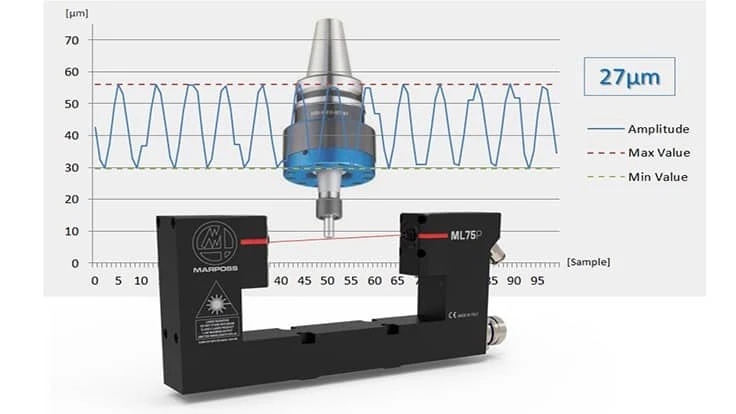

Marposs’ ML75P special edition laser tool

setter for controlling ultrasonic tool vibration amplitude and frequency collects

thousands of data samples from the vibrating tool tip within milliseconds using

ML4USM software. The software then elaborates upon the signal and transfers the

amplitude and frequency back to the machine for automatic compensation. This

helps to improve tool life and workpiece finish and reduce downtime.

Ultrasonic machining removes material from

a workpiece using high-frequency vibrations in combination with abrasive

particles. By creating many small vibrations over time, material is removed

from the workpiece. Ultrasonic machining is the most suitable technology for

removing material from hard and brittle materials, such as ceramic and glass.

In addition to the ML4USM software

application, theML75P special edition requires a dedicated measurement cycle for the

ultrasonic machining. It is designed to work with either a Marposs Merlin Plus

or GEM Box gauging computer, both of which run on the Microsoft Windows operating system.