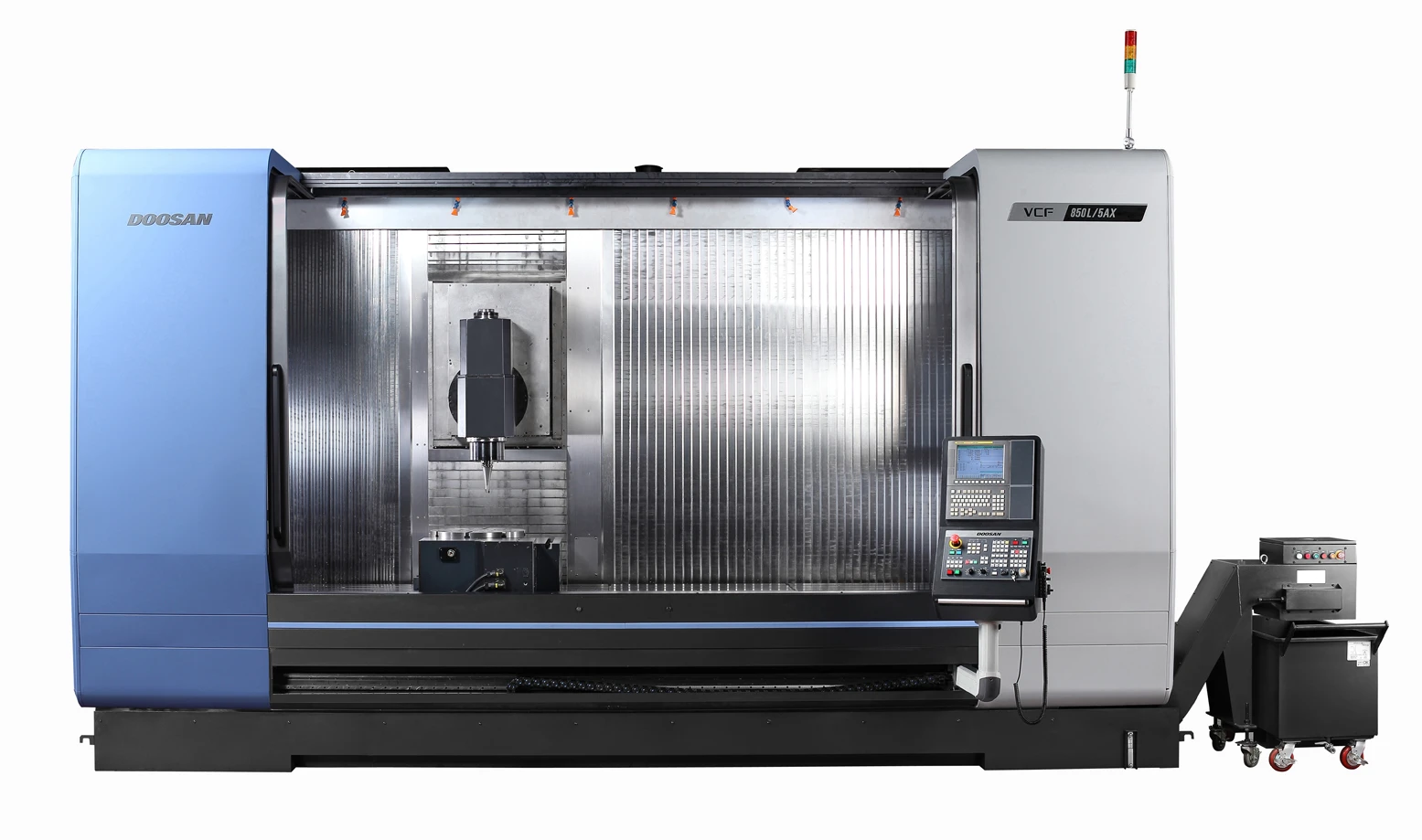

The VCF 850LSR is a large capacity, travelling column design, vertical machining center with a tilting B-axis head. Its design allows for machining on multiple sides of a workpiece at once. The head can rotate 110° on either side of vertical, enabling the VCF 850LSR to machine large and complex parts in a single setup, eliminating fixtures and downtime. With its included 500mm (19.685") rotary table, up to five sides of a part can be accessed.

Bed, column, and saddle

The bed is a rigid, one piece casting made from fine grain Meehanite cast iron with heavy ribbing to help prevent vibration and deformation during heavy cutting. The roller guideway’s wide spacing supports the saddle in all positions and with no overhanging, regardless of its load distribution. Featuring a traveling column design, the table, and the workpiece, remains locked during machining. This design provides a uniform load to the guideways, ball screws, and motors.

Guideways

All axes are of a Roller Linear Motion Guide type for high stiffness, accuracy, and surface finish. They are both heavy duty (X - 45mm/1.772", Y - 45mm/1.772", Z - 45mm/1.772") and widely spaced (X - 655mm (x2)/25.787", Y - 720mm/28.346", Z - 560 mm/22.047"). Roller guideways are three times more rigid with 2 times more life than ball bearing guideways and provide for optimal weight and force distribution.

Ball screws and axis drives

Each axis is driven by a high precision double nut ball screw that is centered between the guideways and supported on both ends by angular contact thrust bearings. All ball screws are cooled by circulated, refrigerated oil at all critical components including the ball nut, support bearings and the motor housing. This system, coupled with a double pretension design, provides excellent positioning repeatability with virtually no thermal growth. All axes have large diameter ball screws (X - 63mm/2.480", Y - 50 mm/1.968", Z - 50mm/1.968") that are directly connected to oversize AC servo drive motors without gears or belts in order to help eliminate backlash.

Glass scales on X, Y, and Z Axes

The X, Y, and Z axis utilize absolute type linear glass scales for higher positioning accuracy that do not require referencing at power up. The scales virtually eliminate the impact of slides and ball screw thermal expansion and backlash. This improves the ability to hold tight part tolerances with fewer offset changes.

Rotary table

The supplied Doosan D500 rotary table allows for machining on multiple faces of the work piece without having to re-fixture. This allows for reduced number of setups and much higher precision of the finished component. With 4 + 1 axes of simultaneous motion, very complex shapes are able to be produced, and when coupled with the machine’s ability to rotate the spindle head (+110° \ -110°), it is possible to machine five sides of a work piece in a single setup.

Built-in spindle motor

The powerful, 12,000rpm, built-in drive spindle motor has 18.5/22 kW (25/29.5 hp) and 147.25nm (108.60ft-lbs) of torque. This design promotes thermal stability and keeps vibration at higher rpm to an absolute minimum. A refrigerated cooling control system circulates cooling oil around the spindle in order to maintain a constant temperature, increasing accuracy regardless of the ambient temperature of the cutting conditions. The CAT 40 Big Plus spindle system is a true cartridge type unit supported by high precision, permanently grease lubricated ceramic ball bearings with a spindle acceleration/deceleration time of 0 to 12k (1.3 seconds)/12k to 0 (1.5 seconds). An encoder is attached to the spindle to allow rigid tapping, further increasing productivity.

B-Axis tilting headstock

The headstock is mounted to a rigid swiveling base that is driven by a heavy-duty and high-precision worm gear. This design allows the spindle to present tooling to the workpiece at any angle between +110° to -110° from vertical, enabling machining on multiple sides of the workpiece at once. The B-axis is capable of 900ft-lbs of torque during contour machining or can be locked down by means of a hydraulic piston with 1,475ft-lbs of torque for heavy duty cutting. Oil cooling around the assembly maintains constant temperature, regardless of the cutting condition, to ensure accuracy.

Big Plus spindle system by Big Daishowa LTD

The Big Plus spindle system and tooling features simultaneous taper and flange contact between the machine spindle and toolholder as well as complete interchangeability with existing machines and tools. Upon mounting the toolholder into the machine spindle, contact occurs prior to clamping. Due to the retention force, the taper of the toolholder expands the machine spindle in its elastic range. The tool is pulled further in until the tool flange touches the spindle face for maximum rigidity.

Automatic toolchanger

The 60 tool, chain type, Double Arm ATC is servo motor driven and provides reliable exchange of tools with a tool to tool time of 1.5 seconds.

20 Bar (230psi) through spindle coolant system (TSC)

A dedicated positive displacement pump delivers the coolant directly to the tool tip. The immediate benefit is more aggressive feeds and speeds can be maintained throughout the cutting process. There is also no need to stop and adjust coolant nozzles, something that increases both in cut time and operator safety. Protecting the spindle and the vital rotary union from contamination is a Cyclone filter that does not require the use of bags, reducing maintenance costs and downtime. The 360 liter (95 gallon) tank stores an ample supply of coolant and is isolated from the machine bed to help prevent heat transfer.

Portable manual pulse generator

The handheld Manual Pulse Generator lets each axis move in increments of x1, x10 or x100, making fixture or part alignment quick and easy. The 10ft cord gives full access to the machine and the magnetic back allows for one handed operation with the MPG being conveniently held in place on the machine table or guarding.

Program and data protection key switch

The keyed switch enables the protection mode for both the program and offset data. Removing the key limits access to only authorized personnel. In the unprotected position the key cannot be removed and all data is available for edit.

PCMCIA/USB card slot

The Fanuc 31-iB series control is equipped with a slot for a PCMCIA and USB port on the control next to the display. A PCMCIA memory card can be used to upload and download programs as well as drip feed directly from the card. Programs running from the card will take the same time to run as a program that is stored in the control memory. It is possible to search through and restart anywhere in a program as long as it contains line numbers. The USB Port does not allow you to drip feed; it is only for uploading and back up of programs and parameters.

Swiveling operator panel

The control is mounted on a pendant that can be positioned anywhere along the door opening via a rail and can swivel up to 180°. This allows the operator a clear view of the working area wherever the work piece is positioned or machining is taking place.