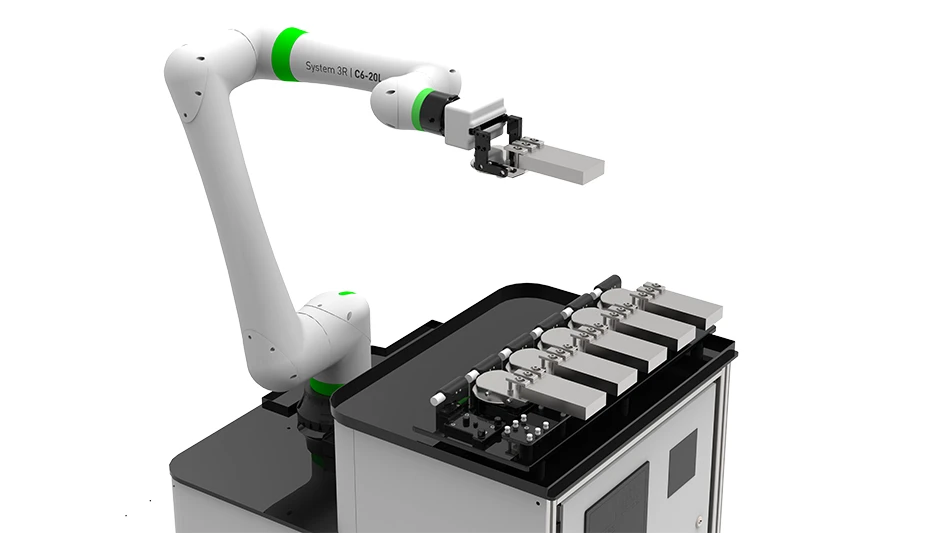

CREDIT: SYSTEM 3R

The developed cobot solution C6-20L from System 3R is in line with the company’s lights out factory vision. This as the trend of using Autonomous Mobile Robots (AMRs) has become increasingly important for industry.

The cobot solution C6-20L is unique from a process point of view – securing the process for the customer and use sensors and ID in combination with WorkShopManager (WSM) software. Additionally, System 3R uses floor scanners so the operator can always interact with the cobot magazine and make necessary changes while the robot stops. Add/remove or change place in the magazine, and when the operator moves out from the magazine area, it will be re-scanned, and the robots start again. This will ensure a process safe way of making changes. And as well a safe way of interacting with the cobot. As it’s a cobot and works in collaborative mode, it’s always safe from operator point of view.

The cobot and all other 3R robot types/cells can be provided with the software system WSM and ID. The latest generation WSM 5.0 supports AMRs and will be presented at EMO.

WSM 5 allows seamless integration at a factory level, and intuitive interface for managing complex and multi-technology workflows. Maximum flexibility guaranteed by simple drag-and-drop priority change by the operator on the Automation control panel.

Automated systems eliminate human error and allow tracking of each workpiece, resulting in consistent output and reduced downtime.