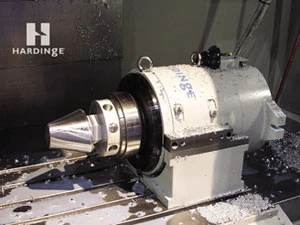

Hardinge's newest Quick-Change Rotary Systems incorporate a direct-drive, rare-earth permanent-magnet torque motor. This frameless motor wraps around the spindle, eliminating the need for a separate motor extension, and resulting in a much smaller footprint. The ± 0.077arc/sec resolution, ± 2.19arc/sec accuracy encoder is mounted directly on the spindle to ensure extremely accurate positioning.

The A2-5, 16C High-Torque Direct-Drive Rotary System is ideal for difficult, high precision machining, or jig grinding applications requiring 4-axis or 5-axis interpolated machining, or for parts that require extremely accurate angular positioning. A pneumatic collet closer is equipped with a dual cylinder resulting in 4,560lbs of adjustable draw bar pull. A 7-in. spindle centerline height will accommodate a large 305mm diameter slotted faceplate.

The A2-4, 5C High-Speed Direct-Drive Rotary System is designed to position extremely fast with a high degree of accuracy and without backlash. A 3,600°/sec indexing speed combined with the gearless direct-drive features make this indexer ideal for drill and tap, laser processing, and intricate or high-speed milling applications. A 4-in. spindle centerline height and a fail-safe, through-hole collet closer is standard. The High Speed System is offered as both an integrated fourth axis, or as a stand alone indexer driven by Hardinge's all-digital, user-friendly servo control.

Hardinge, Inc.

Elmira, NY

hardingeusa.com