Quality Vision International (QVI), the world’s largest vision metrology company, will designate a portion of its IMTS 2014 Booth E-5602 as a “Shop Floor Zone,” to showcase unique shop-floor-ready measurement solutions, September 8-13, in Chicago.

QVI has assembled a variety of measuring systems from each of its divisions for inclusion in the Shop Floor Zone. These systems range from simple manual measuring machines, to fully automated programmable systems with multisensor measurement capability, to a large-field-of-view system integrated with a robotic part handler in an automated work cell. Each machine will demonstrate its ability to quickly and accurately measure various industrial parts in a shop floor setting. The common denominator of these systems is their convenient operation and reliable performance in typical industrial conditions on the shop floor. Shop-floor-ready systems to be shown are —

SmartScope Flash 200, from Optical Gaging Products (OGP), demonstrating its multisensor measurement capability, as well as parametric part programming using the new ZONE3 3D CAD-based metrology software.

CC-14 14-inch optical comparator, from Certified Comparator Products (CCP), showing how easy it is to accurately measure metal stampings using its eCAD virtual chart system.

C-vision Benchtop Video Contour Projector, also from CCP, demonstrating the power of an automatic vision system married with the convenience of a shop-floor comparator, measuring an orthopedic hip stem mounted on a rotary.

The compact VICI Vision MTL 1 measuring system, offered by Optical Gaging Products, demonstrating high speed optical measurement of length, diameter, threads, roundness, and concentricity of small turned parts up to 300 mm long.

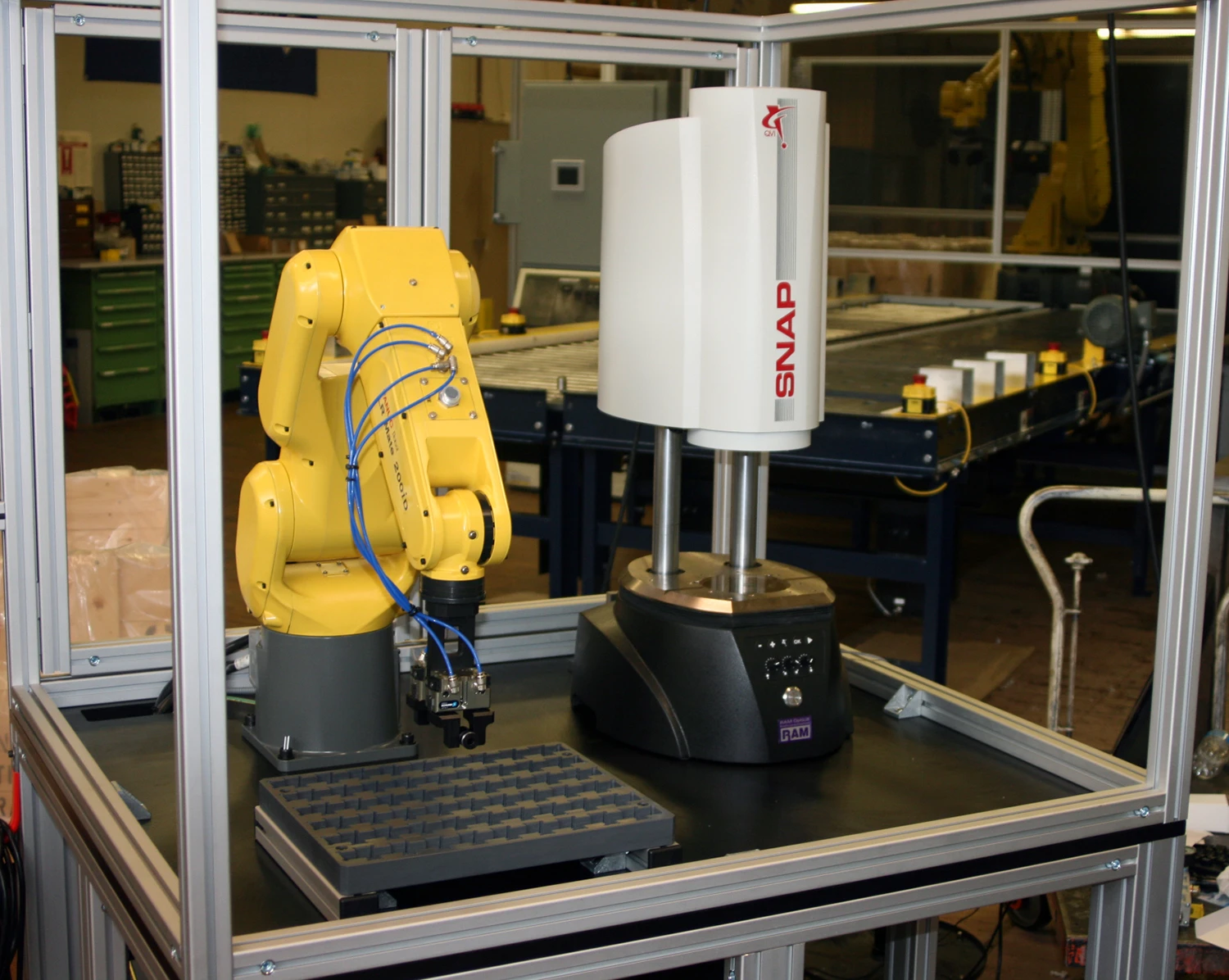

With telecentric optics and versatile lighting, the SNAP Large-Field-of-View measuring system, from RAM Optical Instrumentation, demonstrating its integration with an automated robotic part handling system, for potentially complete 24/7 lights-out operation.