Process Chain Integrated Simulation

Simulation has established itself as an invaluable tool to aid molders and mold makers in providing high-quality parts, delivering them in time and for competitive prices. SIGMA® Plastic Services, Inc. provides 3D polymer system simulation software, maintenance and support, as well as engineering services using our proprietary tool SIGMASOFT®. Process chain integrated simulation means to make simulation accessible to "everyone". SIGMASOFT® has been lauded as "The Next Generation of Plastic Simulation" by our customers and competitors because of its unique combination of ease-of-use and its capability to consider all details of an entire mold. This, for the first time, opens the utilization of this technology to designers with product responsibilities and production engineers, as no Finite Element meshing experience is required to use it. SIGMA® is determined to provide everyone who is involved in manufacturing plastic parts with comprehensive, accurate yet easy-to-use software.

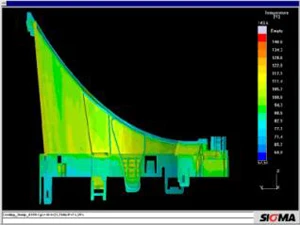

3D Polymer System Simulation

The utilization of SIGMASOFT® enables molder and mold makers to drastically reduce their "time-to-market" processing time by the reduction or elimination of prototypes, as well as trial and error runs. Costly modifications of molds, especially when it is discovered that they must be implemented during the ramp up of the series production, can be avoided. SIGMASOFT® is the most accurate 3D polymer system simulation software in the market covering thermoplastic, elastomer, silicone rubber, thermoset and MIM/CIM materials. It is unique in its combination of ease-of-use, accuracy, and speed to solution, even for highly complex parts with non-uniform wall thickness designs.

Latest developments:

Two significant features of version 4.7 are ejection process simulation and the control of heaters by PI controllers. Ejection: This unique functionality simulates the ejection process and enables the process engineer to determine precisely when the part has become sufficiently stiff enough to withstand the forces of ejection. In addition, the mold engineer can find the optimal ejector configuration. It can be detected which ejectors are critical and those that do not contribute much to the process. Lastly, the production engineer can assess part deformation due to the ejection action.

Simulation of the ejection process of a dog bone test bar PI controller: SIGMASOFT® applies and controls the wattage put into a heater's geometry. This functionality helps to determine the best position for heater and thermocouple. The PI controller functionality supports SIGMASOFT® capabilities in simulating thermoplastic hot-runners and elastomer / LSR molds.

Summary of unique capabilities and industry-firsts found in SIGMASOFT®:

- Automatic 3D meshing of the entire mold (mold plates, slides, air gaps, part, runner, tempering geometries...) within seconds.

- Consideration of all geometry's with their true, temperature dependent material properties

- PI-controlled heater geometry's

- Simulation of thermoplastic hot-runners / elastomer cold-runners

- Simulation of the ejection

- Simulation of crystallization

- Simulation of the curing reaction

- Simulation of a 2nd heating cycle

- Shrinkage & warpage simulation considering stress relaxation

- Multi-shot simulation of two and more components

For More Information

Christof Heisser or Matt Proske SIGMA Plastic Services, Inc. 10 N. Martingale Road, Suite 425 Schaumburg, IL 60173 Tel. (847) 558-5600 www.3dsigma.com contact@3dsigma.com