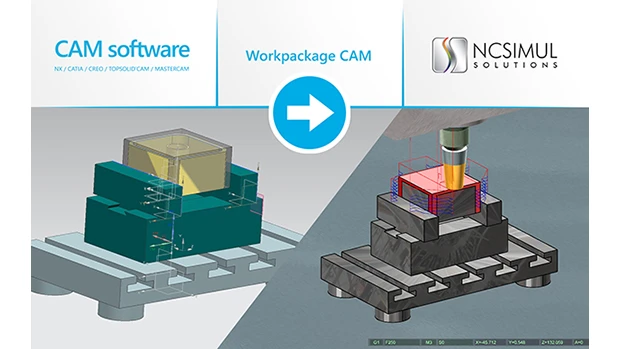

SPRING Technologies, vendor of software for the optimal and flexible use of Numerical Control machines, announces the launch of its CAM WorkPackages, a set of interfaces between commercially available CAM solutions and NCSIMUL 4CAM (formerly NCSIMUL CAM). WorkPackages are provided for for CATIA (Dassault Systèmes), NX (Siemens), CREO (PTC), TopSolid’Cam (MISSLER), and Mastercam (CNC Software, Inc.). Ultimately, SPRING Technologies plans to offer its users direct interfaces with all the leading CAM products on the market.

NCSIMUL 4CAM is a powerful, innovative solution that is a vital add-on for a CAM deployment that makes production environments even more agile. To do this it must enable users to transparently harness all their CAM project data, so that they can quickly and easily switch from one NC machine to another without writing new code. The CAM WorkPackages provide this capability.

Today, more specifically, NCSIMUL 4CAM enables programmers in any sector of industry to directly and easily retrieve a part assembly, a clamping system and a rough stock model, with the machining and positioning coordinate system data, and associated cutting tool library, without having to go back into the tool path program. In addition to the ISO files, the CAM WorkPackage gives users read access to the following APT files: CATIA, Esprit, GO2CAM, NX, Pro-E, Surfcam, to automatically identify and separate the different machining phases, and facilitate the change to the new machine. This delivers further substantial time-savings when changing between NC machines, addressing production and machine availability imperatives.

This flexibility is primordial for factories that need to remain competitive today and going forward.

Customer benefits include:

- Optimized flexibility to adapt manufacturing to machine availability on the shop floor

- Faster production rates and TRS from their NC machines

- Safer machine changes in one-click, generating a new NC program that is simulated, checked, optimized and validated, whichever NC machine was used upstream or downstream in the process

- Monitoring of all the modifications made following the change of machine in the different machining sequences

- Capitalization on the work of the programmer by automatically reusing information from the CAM

- Dynamic management and exporting of the intermediary rough stocks for instant data checks at all times during the machining phase

From NCSIMUL CAM to NCSIMUL 4CAM… Why the name change?

“To precisely and unambiguously position our product, which is specifically a CAM add-on and not just another CAM software”, explains Gilles Battier, CEO of SPRING Technologies. “We know our strengths and we are making the most of them to deliver innovative technology to our customers, instead of copy/pasting existing solutions. Our aim remains the same: to listen to our customers’ needs and help them as they progress towards Industry 4.0.”

About SPRING Technologies

SPRING Technologies develops software solutions designed to optimize manufacturing companies' CNC machines to reduce costs and maximize productivity.

Its product NCSIMUL SOLUTIONS provides a complete and integrated mastery of the production process from Methods departments to Workshop including NC programming, machining simulation, cutting tool management, CNC program management and real time machine status monitoring.

This unique approach simplifies the digital chain and provides needed tools and flexibility for the implementation of automated factories.

Based in France, Germany, PR China and the USA, the company was founded in 1983 and collaborates with manufacturers in aerospace and defense, transportation, energy, industrial equipment and medical devices, using CAM software's such as CATIA, NX, CREO, TOPSOLIDCAM, MASTERCAM... Through its global network of resellers, SPRING supports its customers all over the world.

Source: SPRING Technologies