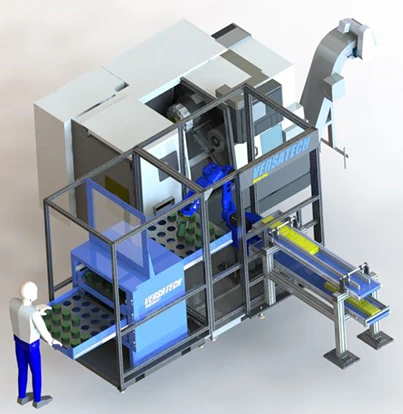

Effingham, Illinois - Versatech, LLC is now offering the VersaCELL Robotic Machine Tending Cell to help machine shops, job shops, and manufacturing facilities mitigate the workforce skills gap. This innovative automation solution uses robotic technology to perform machine loading and tending functions, reducing manpower requirements for a two machine production center by as much as 66%

Check out the 2016 IMTS Conference!

No more manning each CNC lathe, grinding operation or machining center with multiple operators. After the VersaCELL is installed, an operator is only needed to load and unload parts from the conveyor, the entire cell doesn’t even require a dedicated operator.

The operator simply loads parts onto the included conveyor or drawer system. VersaCELL then performs the following operations for up to two machine tools:

• Unloading parts from conveyor or drawer system

• Loading parts into the machine tool using customizable end of arm tooling

• Unloading parts when machining operation is complete

• Transferring parts to second operation for additional machining, if applicable

• Stacking finished parts in drawer or on conveyor to return to operator

The same operator simply performs initial loading and final unloading, with the VersaCELL system doing the rest of the work. In addition, if the drawer system is used, multiple parts can be staged for machining, allowing the operator to complete other tasks while the VersaCELL is working. The VersaCELL Modular Robotic Machine Tending Cell is designed to be easy to set up and install to quickly meet your small to large volume production needs.

The VersaCELL base package includes the following components:

• Robot base (12-24 kg payload)

- You can choose between Motoman or Fanuc robots

- Robot is mounted on linear bearing rails to allow the robot to be moved for manual loading

• Conveyor or Drawer System

• Lightweight, aluminum extrusion construction with wire mesh guarding for safety

• End of arm tooling with either single or dual grippers

While the base package can meet your immediate needs for manpower reduction, you can also customize the VersaCELL to increase functionality and productivity by adding any of the following options:

• Robotic vision system

• Interfacing for 2nd machine tool

• Additional robot and drawer tooling

• Quick change robot tooling

• Re-grip station

• Dual infeed systems

• Touch screen HMI

• Customized workcells

Source: Versatech, LLC