VIMANA Enrich, a software solution that simplifies the capture and integration of relevant data from the shop floor, manufacturing, and business systems and adds context to the manufacturing process without increasing time and cost for programming and systems integration, is now available.

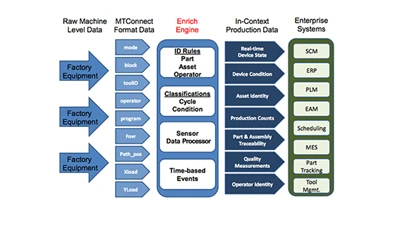

A key challenge to Smart Manufacturing is building better data, this depends on automatically capturing, structuring, and adding context by integrating machine data with other manufacturing data sources. VIMANA Enrich solves these challenges and allows manufacturers to be able to identify the true state of the manufacturing process such as current machine activity, asset health, part production, and operator status. Additionally, events and alerts can be created for insight into needed actions focused on maintenance, scheduling, inventory, part quality, etc. Enabling end-to-end process automation, VIMANA Enrich integrates with other upstream CAM and downstream ERP, scheduling, and maintenance systems.

VIMANA Enrich is a stand-alone, on premise, streaming application that consumes data from MTConnect and other data sources. It leverages a set of standard and custom developed rules to generate events that can be consumed by VIMANA Utilize or other analytics platforms for visualization and predictive analytics. Enriched data can also be integrated with other manufacturing and business systems to include enterprise resource planning (ERP), maintenance, and scheduling systems to enable a closed-loop process and end-to-end supply chain automation.