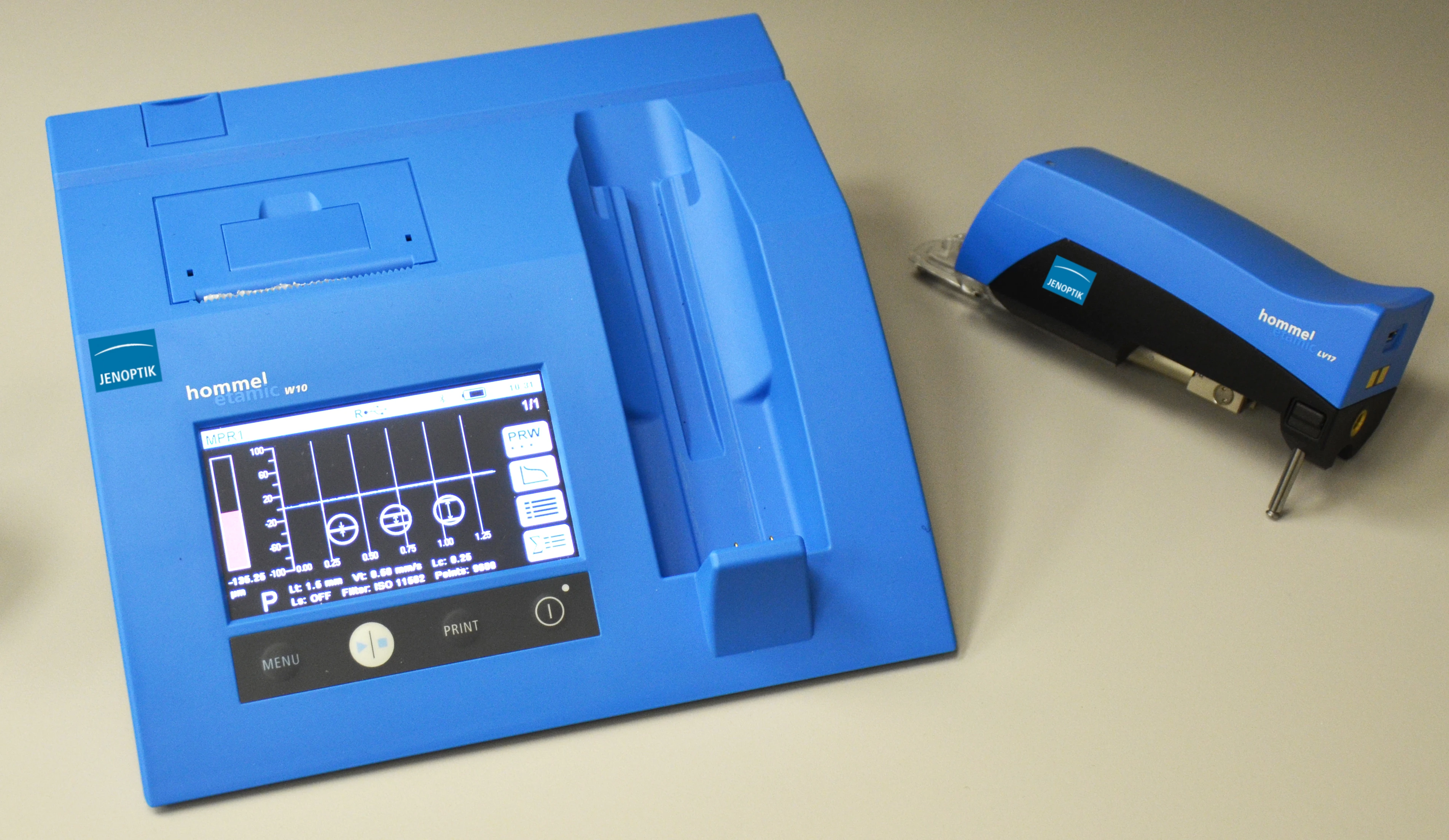

To be highlighted at IMTS 2014 Booth E-5545, the Jenoptik W10 mobile surface roughness measuring system is ideally suited for measurements on the production line or machining cell. The new instrument’s remote measuring capability brings the measurement lab to the shop floor. Light and compact in design, easy to operate with long-lasting battery power, the W10 is simple to use. Operation is intuitive through the easy to understand graphic user interface. More than 800 measurements with one battery charge guarantee a high level of reliability even during frequent use. Measuring results may be quickly printed out on the integrated printer—wirelessly via Bluetooth technology.

Capable of checking more than 40 roughness and waviness parameters using an extensive array of probes and accessories, the new W10 can match the performance of more expensive stationary systems with its accuracy and precision.

The new Jenoptik W10 is ergonomically designed, with the device easily fitting into the user’s hand making it simple to precisely position on the workpiece. The wireless device can be used for transverse probing, overhead measurement, mobile measurement on small shafts, perpendicular measurement, and is equipped with tripod legs to adapt to small workpiece height. An integrated V-groove securely positions small shaft type parts on the unit for measuring.

The W10 is capable of tracking eight separate measurement programs, including one for device verification, up to 100 separate profiles, with a total storage capacity of up to 10,000 completed measurements.

The integrated click wheel allows the operator to intuitively select device functions. In conjunction with the large color display with graphic interface, this makes operation of the W10 simple and transparent, delivering easy to see results and tolerance evaluations.

The roughness probes and measuring instrument electronics are calibrated independently from each other at the factory. This eliminates the need to make regular adjustments to the amplification or to recalibrate —a big advantage for everyday measuring.

Height adjustment integrated from factory

The extendable tripod legs can be used to adjust the measuring instrument to the height of small workpieces. This allows such measuring applications to be implemented without an additional means of holding.

Measurement on small shafts

The support prism centers workpieces like small shafts from 10mm diameter reliably on the correct measuring position and protects the probe for measurements in bores from 12 mm diameter.

Precise workpiece support

The contact to the workpiece is made by precisely polished sup¬port shafts. This guarantees permanent, stable workpiece support. A height measuring stand can turn the W10 in a complete measuring station for tasks that require precise positioning.

Tolerance evaluations at a glance

The colored display of the measurement results depending on the tolerance evaluation allows the measurement results to be assessed at a glance.

Measurement position lighting

The transparent probe cover combined with the measure¬ment position lighting makes the exact measurement positi¬on of the roughness probe very easy to see. This makes the positioning of the measurement easier when it counts.

One connection — many functions

No risk of confusion: all the necessary functions are covered with just one USB port:

• Battery charging function or permanent power supply

• USB connection to PC to transfer parameters and profile data

• External controls via foot switch

• Remote controls

With the optional TURBO DATAWAVE basic software the measurement results from the W10 can be transferred into an Excel spreadsheet on a PC for further processing and documentation.

TURBO DATAWAVE expert – professional evaluation software with a simple menu guide

TURBO DATAWAVE expert is optional evaluation software for PC-controlled programming and parameter analysis and provides the ability to control the W5 remotely

Integrated printer

The thermal printer built into the W10 documents the measurement results on the spot — using Bluetooth® without awkward cables. The roughness measuring instrument remains mobile, even if the measurements need to be documented.

Easy to insert paper thanks to “Easy Paper Loading” technology: insert roll of paper, close cover, done. The printer is controlled from the roughness measuring instrument.

The robust, fiber glass-reinforced plastic casing is desi¬gned for industrial use. Up to five rolls of paper can be printed with one battery charge. Measuring conditions, parameters, tolerance evaluati¬on, roughness profile and Abbott curve: depending on the measuring program, this information can be printed off individually or in combinations.

Jenoptik W10 specifics:

Total deviation acc. to DIN 4772 Class 1

Measurement range/resolution 320 microns

Probe is an inductive skid probe

Measurement display is micron/microinch selectable

Max. traverse length is 17.5 mm

Traverse speed 0.15 / 0.5 / 1 mm/sec; return: 3 mm/sec

Individual traverse lengths 1-5 selectable

Filter Phase-correct profile filter (Gauss), in accordance with ISO 11562 Filter in accordance with ISO 13565-1

Data point interval minimum of 0.5 micron (9600 points when lt = 4.8 mm)