CREDIT: MAZAK

Mazak Corp. sets its sights on the latest manufacturing and automation technology specifically for aerospace, medical, space exploration, defense/marine defense, and other area industry component production at its two-day Florida Open House February 18 to 19 from 10AM to 6PM. Located at its Mazak Technical Center located in Orlando, the event will feature a variety of machines and automation in action processing real-world parts and provide access to applications engineers for expert manufacturing advice.

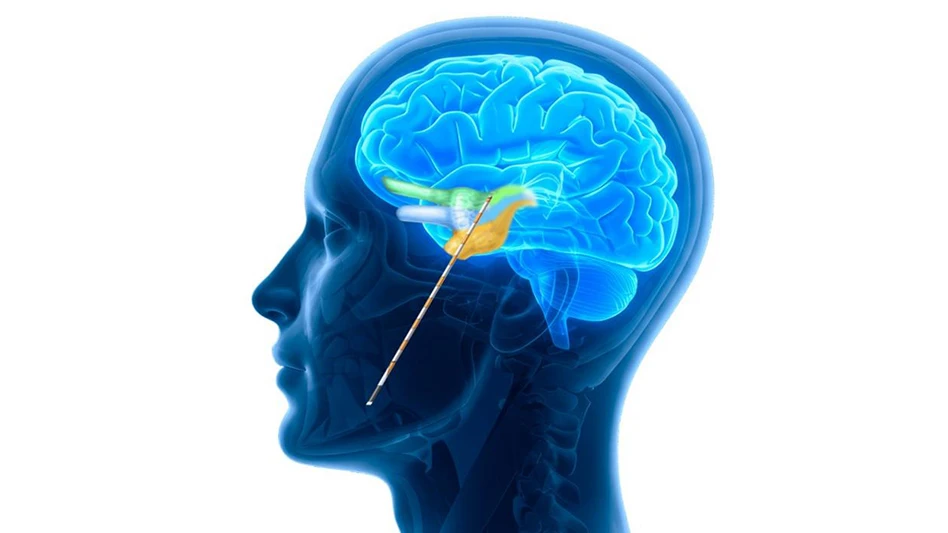

Live demonstrations will include Mazak’s QTE-100MY Multi-Tasking Machine outfitted with bar feeder automation, a VARIAXIS C-600 Vertical Machining Center and a SYNCREX 12/8 Swiss-style Production Turning machine. The QTE-100MY features milling (M) and Y-axis off-centerline capability (Y) for both turning and milling part production, while the VARIAXIS C-600 allows for multi-surface and full simultaneous 5-axis machining. The Swiss-style Production Turning machine processes small, extremely high-precision parts with its eight axes and maximum bar diameter capacity of 0.4724" (12mm).

Equipped with a 6" chuck, Mazak’s QTE-100MY’s integral turning spindle reaches a maximum speed of 6,000rpm, and the machine handles part diameters up to 13.39" (340mm) and has a bar capacity of 2" (50.8mm) in diameter. A rotary tool turret spindle further expands the machine’s capability with a 4,500rpm, 7.38hp (5.5kW) milling spindle along with a 12-tool capacity.

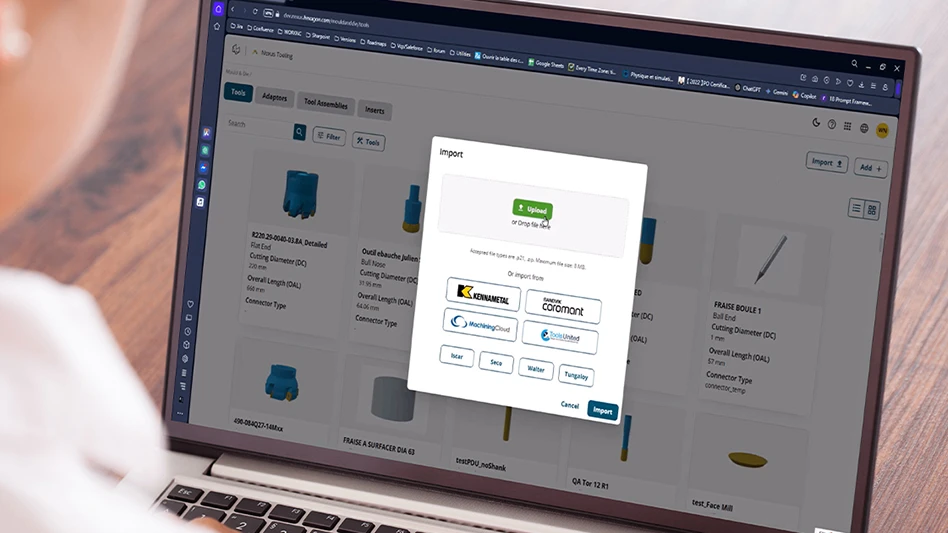

As a solid first step into 5-axis machining for some shops, Mazak’s VARIAXIS C-600 offers four spindle options that allow shops to find the ideal balance of speed and power. In addition to the standard 12,000rpm CAT40 spindle, 15,000rpm, 18,000rpm, and 20,000rpm options are available in CAT 40, Big Plus, or HSK A-63 types. The standard 12,000rpm spindle with a motor output of 11/11kW (40% ED/cont.) and torque of 70/57.3Nm (40% ED/cont.) delivers a high cost-to-performance ratio and is well-suited for machining steel, cast iron, and aluminum. Options for VARIAXIS C-600 tool magazines include those with 30, 60, 90, and 120-tool capacities as well as random access magazines that eliminate the typical wait time with other types of fixed-address tool systems and are ideal for short machining cycle times.

For those manufacturers producing large quantities of small, extremely high-precision parts, Mazak’s SYNCREX 12/8 will demonstrate the production power of Swiss-style Production Turning on an eight-axis machine that handles a maximum turning diameter of 0.4724" (12mm) and provides for up to 27 tools – 19 static and 8 live. The machine is equipped with the MAZATROL SmoothSt CNC that incorporates Mazak’s Swiss Setup Assist (MSSA) for fast and easy job setups and Mazak Dynamic Chip Control (MDCC) functionality. For further ease of use, the MAZATROL SmoothSt CNC functions include tool touch off, part cut off, retract point, and start position. The CNC also allows for synchronous control of all axes, including the ability to simultaneously turn and drill, along with rigid tapping with all spindles.

Latest from Today's Medical Developments

- Experts discuss the latest in toolholding technology

- How permanent magnets are powering medical innovation

- Forecasting the year ahead in design and manufacturing

- Tecomet, Orchid Orthopedic Solutions announce merger agreement

- Resonetics acquires manufacturing assets, process IP from Med-Ally

- Trelleborg’s medical device solutions highlighted at MD&M West

- Arterex expands medical device design, manufacturing platform with Synecco acquisition

- Medical-grade thermoplastic resin